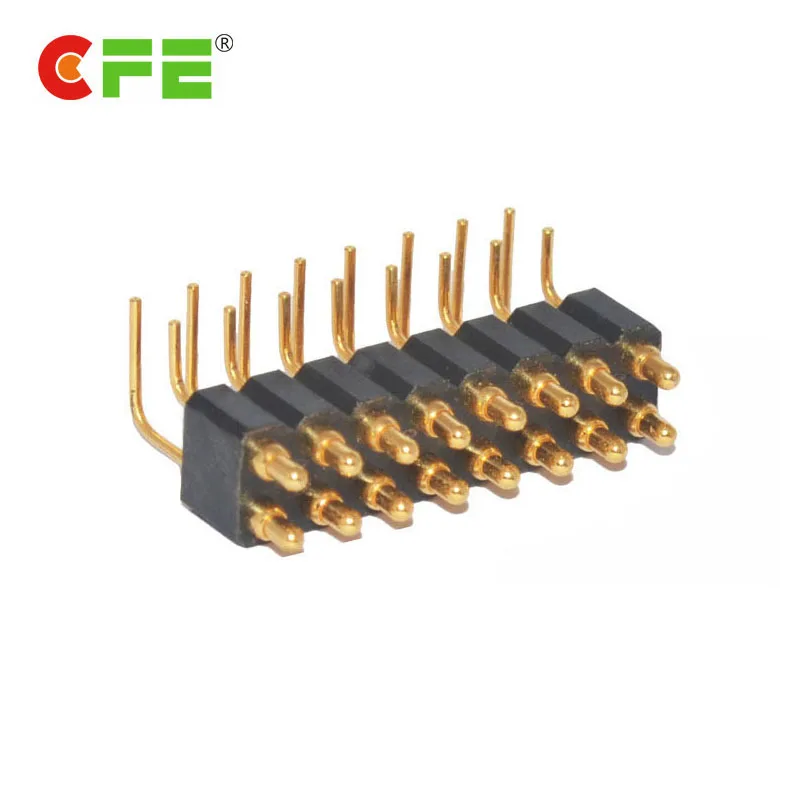

They can also be used for more permanent connections, for example, in the Cray-2 supercomputer. In one extremely high-density configuration, the array takes the form of a ring containing hundreds or thousands of individual pogo pins this device is sometimes referred to as a pogo tower. They are commonly found in automatic test equipment in the form of a bed of nails, where they facilitate the rapid, reliable connection of the devices under test (DUTs). When pogo pins are used in a connector, they are usually arranged in a dense array, connecting many individual nodes of two electrical circuits. laptop docks and chargers (see § Combination with magnets) Magnetic charging or signal connectors, e.g.Ingress-protected connectors in consumer devices, e.g.

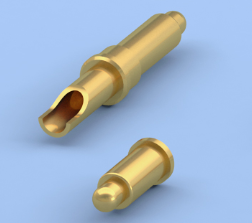

For example, a ball may be added between the two components, or the plunger may have an angled or countersunk tip. Many manufacturers have created their own proprietary variations on this design, most commonly by varying the interface between the plunger and spring. In order to counter this, the plunger usually has a small tilt to ensure a continuous connection. Since a spring-loaded pin needs to have a slight gap between the plunger and barrel so that it can slide easily, momentary disconnections can happen when there is vibration or movement. Thus, a precise normal force, typically around 1 newton, is required to generate this friction. However, high friction is undesirable because it increases stress and wear on the contact springs and housings. In the design of electrical contacts, a certain amount of friction is required to hold a connector in place and retain the contact finish. The shape of the barrel retains the plunger, stopping the spring from pushing it out when the pin is not locked in place. When force is applied to the pin, the spring is compressed and the plunger moves inside the barrel. Spring-loaded pins are precision parts fabricated with a turning and spinning process which does not require a mold, thus allowing the production of smaller quantities at a lower cost.Įxploded diagram showing components of a standard pogo pinĪ basic spring-loaded pin consists of 3 main parts: a plunger, barrel, and spring. Targets may be separate components in the complete connector assembly, or in the case of printed circuit boards, simply a plated area of the board.

A pogo target consists of a flat or concave metal surface, which unlike the pins, has no moving parts. Ī complete connection path requires a mating receptacle for the pin to engage, which is termed a target or land. This helical spring makes pogo pins unique, since most other types of pin mechanisms use a cantilever spring or expansion sleeve. The name pogo pin comes from the pin's resemblance to a pogo stick – the integrated helical spring in the pin applies a constant normal force against the back of the mating receptacle or contact plate, counteracting any unwanted movement which might otherwise cause an intermittent connection. They are used for their improved durability over other electrical contacts, and the resilience of their electrical connection to mechanical shock and vibration. Sectional drawing of a pogo pin, showing the plunger, barrel, and springĪ pogo pin or spring-loaded pin is a type of electrical connector mechanism that is used in many modern electronic applications and in the electronics testing industry.

0 kommentar(er)

0 kommentar(er)